IDENTIFICAREA VARIABILELOR PROCESULUI DE AGLOMERARE

VARIABLES IDENTIFICATION OF AGGLOMERATING PROCESS

Rezumat

Lucrarea prezinta cateva elemente privind identificarea variabilelor procesului de aglomerare/sinterizare in vederea conducerii automate.

Abstract

This paper presents a few elements regarding the variables identification of agglomeration/sinter process witch helps in automatic management.

|

I. Introducere Procesul de aglomerare/sinterizare are un caracter complex (el functionand ca un sistem complex), fiind influentat de o multitudine de factori ce actioneaza in subsistemele proceselor componente ale acestei tehnologii (fig. 1). S-a analizat aglomerarea ca un sistem, utilizand tehnica de calcul. Minereurile prafoase rezultate in urma proceselor de imbogatire, au in general dimensiuni sub 1 mm, ceea ce conduce la inrautatirea indicatorilor tehnico-economici in cazul participarii lor in proportii mari in procesul de aglomerare /2/. |

I. Introduction The agglomerating/sintering process is very complex (it works like complex system) it is influenced by several factors which action in the subsystems of process components of this technology (figure 1). The agglomeration/sinter was analyzed like a system using a computational system. The powdery ores resulted from the enriching process, has usually dimensions under 1 mm, that is bad for the characteristics techno-economical numbers in case of a large participation of them in the agglomerating process /2/. |

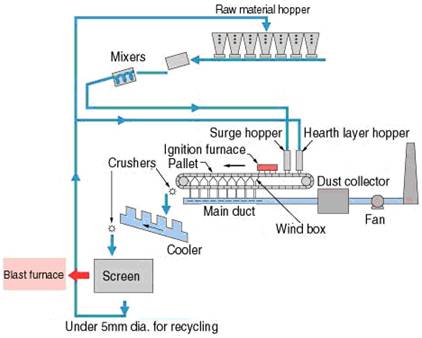

Figura 1. Fluxul procesului de aglomerare

Figure 1. Process flow of sintering

|

Pentru transformarea materialelor fine si marunte in bucati /3/, amestecul omogenizat si globulizat in tobele de amestec sunt depuse pe gratarul masinii de aglomerare intr-un strat de o grosime (inaltime) variabila de la caz la caz. In functie de caracteristici, de tipul permeabilitatii, de capacitatea de aspiratie, natura mineralogica a amestecului si de viteza vertica1a de aglomerare, se stabileste inaltimea stratului de material asezat pe gratarul masinii, supus procesului de aglomerare. Procesul de transformare in bucati a minereurilor marunte si fine are loc pe masina de aglomerare sub influenta caldurii rezultate din arderea combustibilului. Acest proces incepe din momentul trecerii pe sub capul de amorsare, cand se produce aprinderea combustibilului in incarcatura si se produce aglomerarea in stratul superficial. Prin acest strat superficial de aglomerat in stare incandescenta, se aspira aer din atmosfera si se continua procesul de ardere a combustibilului in profunzime. Astfel, dupa aprinderea combustibilului, care dureaza mai putin de un minut, pe stratul de aglomerare de sus in jos se pot distinge cinci zone /4/: - zona de racire a aglomeratului format si de preincalzire a aerului aspirat; - zona de ardere a combustibilului si de aglomerare a materialelor; - zona de incalzire a materialelor; - zona de uscare a rnaterialelor; - zona de umezire a incarcaturii. Automatizarea complexa a procesului de aglomerare inseamna cunoasterea tuturor interdependentelor existente intre factorii implicati in proces /3,6/, aspect care ne confera posibilitatea controlului si conduceri automate a procesului. In aceasta lucrare, autorii au drept obiectiv principal identificarea variabilelor unui proces complex cum este cel de aglomerare. II. Elemente de identificareDin punct de vedere al capacitatii de aglomerare exista o mare variatie a compozitiei chimice si mineralogice a minereurilor utilizate in incarcatura rnasinii de aglornerare. Din cauza acestor fluctuatii a compozitiei chimice si minerologice, se impune o stabilizare a caracteristicelor fizico-chirnice ale incarcaturi, precum si o functionare a masinii intr-un regim . stationar, cat mai stabil posibil, cu scopul principal de obtinere a unui aglomerat cu indici de calitate (de exemplu, reductibilitate, rezistenta mecanica, continut de fier etc.) cat mai stabili. Acesta este motivul pentru care autorii s-au decis sa intocmeasca un model matematic pentru identificarea variabilelor procesului de aglomerare. Pentru identificarea rapida si corecta a variabilelor s-a facut abstractie de unii parametrii de proces (ca de exemplu: umiditatea, permeabilitatea incarcaturii, reductibilitatea, rezistcnta mecanica etc) ce nu pot fi masurati in mod continuu. Autorii au mai folosit, in munca lor de elaborare a modelului matematic, o serie de parametrii, cum ar fi: Parametrii care caracterizeaza sarja de aglomerare: compozitia chimica a materialelor intrate in amestec (minereu omogenizat, calcar); compozitia chimica a minereului omogenizat, (Fe, Mn, MgO, Al2O3, SiO2, CaO); compozitia chimica a calcarului; cantitatile de amestec incarcate pe masina. Parametrii caracteristici ai aglomeratul: compozitia chimica a aglomeratului (Fe, Mn, MgO, Al2O3, SiO2, CaO); cantitatea de aglomerat expediata la furnale. Parametrii caracteristici ai instalatiei de aglomerare: viteza masinii de aglomerare (vm); latimea masinii (Bm); inaltimea masinii (Hm). Pentru a se putea realiza o conducere complexa cu calculatorul a procesului de aglomerare, este necesara o verificare atenta si eventual complectare a aparaturii de masura si control, cu scopul detinerii de informatii sigure si precise asupra tuturor parametrilor utilizati. Modelul matematic propriu-zis are o forma compexa. III. ConcluziiModelul maternatic rezultat si partial prezentat in aceasta lucrare (impreuna cu altele existente sau aflate in lucru) constituie baza pentru optimizarea procesului si conduccrea complexa a instalatiei (masinii) de aglomerare. Dupa elaborarea intregului set de modele si verificarea practica (validarea modelelor), se va creiona modelul final care va permite aplicabilitatea practica si intocmirea schemei de conducere complexa a sistemului. Calitatea aglomeratului este direct, influentata de calitatea materiilor prime folosite, de gradul de pregatire al acestora si de modul de desfasurare a procesului tehnologic de aglomerare /3,4 O mare eficienta economica in procesul de elaborare al fontei se obtine numai in cazul asigurarii furnalelor cu o incarcatura constanta in ceea ce priveste compozitia chimica si caracteristicile mineralogice. Aglomeratul fiind in prezent componentul principal al incarcaturii furnalelor, calitatea lui hotareste in mare parte procesul din furnal. Din cauza variatiilor in limite largi a compozitiei chimice si a caracteristicilor granulometrice ale minereurilor utilizate in procesul de aglomerare din tara noastra, este imperios necesara stabilirea unor balante si retete de aglomerare, bine definite pe baza unor modele matematice. De asemenea, este necesara si o optimizare a formarii stivelor de amestec in conditiile aprovizionarii, care trebuie sa ne conduca la o imbunatatire a calitatii aglomeratului produs. Modelele statistice de analiza a procesului nu rezolva problema referitoare la modul de decizie pentru conducerea lui. Din aceasta cauza s-au stabilit parametrii optimi de functionare ai masinii. Pentru acest lucru, s-au dezvoltat in paralel metode de optimizare a proceselor care utilizeaza metode de programare liniara. |

For sintering materials fine and minime in scrap /3/, the homogenous and spheroid moulding mixture obtained into mixture drum is deposed on the checkered brick-work in a stratum with variable height. Depending on characteristics: type of permeability, absorbency, mineralogical nature of the mixture and the vertical velocity of moulding, we can establish the height of material stratum which is deposed on the grill. The transforming process of minimum and fine ore in compacting is taking place on agglomeration machine under the influence of heat which results from the fuel burning. This process start from the moment when the mixture pass by the rotary sintering kiln and the sinter of superficial stratum start, when the fuel lighting it's happening and product the sintering in the superficial stratum. The air is absorbed from the atmosphere, through the incandescent stratum and the burning of the fuel is continuous. So, after the lighting of fuel, which it takes less than a minute, on the stratum we can see from up side down the following five zones /4/: mixture cooling and air pre-heating zone; fuel burning and materials sinter zone; materials heating zone; drying zone; charge wetting zone. The complex automation of the sinter process involves the knowledge of all interdependencies existents between the factors which affects the process /3 /, aspect which give us the possibility to realize an automatically control of the process. In this paper, authors had the main objective to variables identification of sinter/agglomerating complex process. II. Identification elementsFrom the point of view of the sinter capacity it exist a great variation of the charge ore chemical and mineralogical composition utilization in the charge of sintering belt. Because of those variations of chemical and mineralogical composition is necessary to stabilize the physico-chemical characteristics of charge as well as a steady working conditions for the sinter machine, all this to obtain a mixture with steady quality numbers (reducibility, mechanical resistance, iron content etc.) as much stable. This is the reason for the authors to decide to make the mathematical model for the identification the variables of agglomeration/sinter process. For quick and correct variables identification, we leave aside some process parameters (such as: humidity. charge permeability, reducibility mechanical resistance etc) which can't be continuously measured. Authors used, in our work for the elaboration of mathematical model, another parameters to realize the model, such as: Parameters which characterize the sinter charge: chemical composition of materials for the mixture (homogeneous ore, limestone); chemical composition homogenous ore (Fe, Mn, MgO, Al2O3, SiO2, CaO); chemical composition of limestone; quantities of mixture loaded in the machine. Parameters which characterize the sinter chemical composition of the mixture (Fe, Mn, MgO, Al2O3, SiO2, CaO); quantities of mixture which goes to the furnace. Parameters which characterize sinter machine: velocity of agglomeration (vm); breadth of the machine (Bm); height of the machine (Hm). For the realization an complex management with computer of agglomeration process, is necessary an careful verification and possibly completion of measure and control devices, used that to be made reliable and exactly information about parameter. The mathematical model has a complex form. III. Conclusions The model presented in this paper (with some other which are either existing or in elaboration) consist the base for process upgrade and for a complex leading (machine) by computer of the sinter machine. After elaboration of the entire set of programs and practical verification (models validity), it will be create the final software product witch will allow practical applicability and to draw out scheme for complex system management. The quality of sinter is directly influenced by the quality of the materials used for mixture and by the technological process of sintering /3 /, A great economical efficiency is realized only when a steady charge from the point of view of chemical and mineralogical composition is assured. At his turn, the compound of furnace charge, make the roles of the process inside the furnace. Because of the great variations between large limits of chemical composition and spherical characteristics for the ores which are used in our country is imperative to realize some balances and recipes for sintering well definite based on mathematical models. Also, is necessary an optimization of materials stock, which is important too for the quality of the final product. The statistics models for the sinter process analyze don't solve the problem of 'how take decision' during the leading of the agglomeration process. Therefore, the optimal parameters of sintering machine were established and different methods for optimization of the process based on linear programming were developed in parallel with statistics models. |

Bibliografie/References

[1]Wright, I - A review of process of the development of new ironmaking technologies, ISU - Internationa1, nr 5, 1996

[2]Abramov, V.V.; Kurganov, V.A. - Termo-vravnovescennaia metallurghicescaia izlojnita, Moscova, Metallurghia, 1988

[3]Oprescu,

[4]Butnariu,

[5]Vegman, E.F - Okuskovaie rud I kontentratov, Moscova, Izdatelstvo Metallurghia, 1982

[6]Constantin, N.; s.a. - Modelarea matematica si conducerea informatizata a proceselor din metalurgia extractiva feroasa, U.P.B., Bucuresti, 1997

[7] www.lfa.uni_wuppertal.de

|

Politica de confidentialitate |

| Copyright ©

2026 - Toate drepturile rezervate. Toate documentele au caracter informativ cu scop educational. |

Personaje din literatura |

| Baltagul – caracterizarea personajelor |

| Caracterizare Alexandru Lapusneanul |

| Caracterizarea lui Gavilescu |

| Caracterizarea personajelor negative din basmul |

Tehnica si mecanica |

| Cuplaje - definitii. notatii. exemple. repere istorice. |

| Actionare macara |

| Reprezentarea si cotarea filetelor |

Geografie |

| Turismul pe terra |

| Vulcanii Și mediul |

| Padurile pe terra si industrializarea lemnului |

| Termeni si conditii |

| Contact |

| Creeaza si tu |